As attention to environmental friendliness increases worldwide, the air conditioning industry is committed to improving energy efficiency and reducing environmental impacts. Heating, ventilation and air conditioning equipment consumes a significant portion of the energy in buildings, which is why it is a center of innovation. One of the most significant achievements contributing to this shift is the use of microchannel heat exchangers, products that directly affect the reduction of energy consumption, refrigerant consumption and increase the service life of equipment.

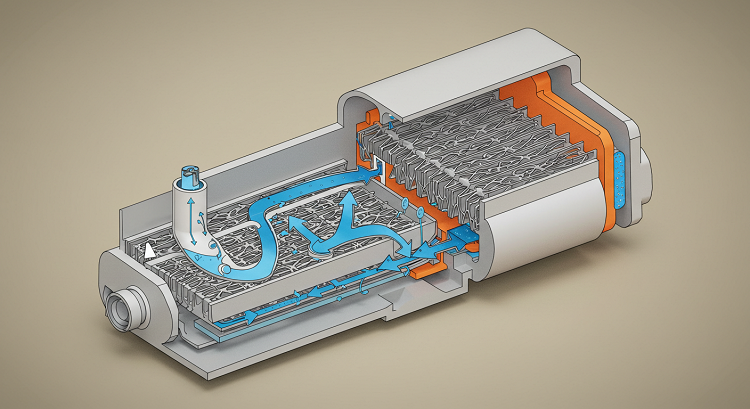

Microchannel heat exchangers are flat aluminum tubes with multiple internal flow channels. This design allows you to increase the surface area, while ensuring an even distribution of the refrigerant, providing higher and more stable heat transfer compared to copper-aluminum heat exchangers. As a result, system performance increases with lower energy consumption, which is an important factor in the design of environmentally friendly buildings.

Microchannel technology is one of the important achievements in the field of environmental friendliness, as it uses a much smaller volume of refrigerant and operates with high efficiency. Microchannel heat exchangers consume 30% less refrigerant than conventional coils, but provide the same level of cooling or heating efficiency. This reduction not only reduces operating costs, but also allows switching to refrigerants with low GWP, which is required in accordance with environmental regulations. As the industry is gradually moving away from liquids with high GWP, such as R-410A, the compatibility of microchannel heat exchangers with next-generation refrigerants makes them a strategic component of next-generation HVAC systems.

Microchannel heat exchangers not only increase the amount of refrigerant, but also improve thermal performance. Their internal design minimizes pressure drop while maximizing heat dissipation, which allows the compressors to work better and consume less energy. In commercial structures, data centers, and residential complexes where the air conditioning system operates continuously, this results in significant energy savings and reduced carbon dioxide emissions, which are key indicators in building sustainability ratings such as LEED and BREEAM.

The compactness and low weight of microchannel heat exchangers also contribute to achieving environmental protection goals. Traditional heat exchangers tend to be heavier and bulkier, which requires additional support structures and high-density manufacturing processes. Microchannel analogues use less raw materials without compromising performance. The lower weight facilitates installation, reduces harmful emissions during transportation and simplifies integration into modern mechanical structures with limited space, which is ideal for upgrading existing systems or creating new high-performance systems.

Durability and long-term environmental benefits

Environmental friendliness is not only energy efficient, but also durable. One of the main problems with traditional heat exchangers is that they are susceptible to formic corrosion, especially in areas prone to gas formation due to adhesives, carpets or cleaning agents. This leads to leaks, constant replacement, and massive waste generation over time.

Microchannel heat exchangers, made mainly of aluminum and often coated with protective hydrophilic coatings, are more resistant to these destructive factors. The smooth internal flow channels in these devices are resistant to contamination, and fewer solder joints mean fewer possible leak locations. This leads to a longer service life, a reduction in unplanned maintenance, and a reduction in overall lifecycle costs, which is directly related to the goals of economic and environmental sustainability.

In addition, the corrosion resistance of microchannel heat exchangers allows them to work best in marine environments, in industry and in high humidity conditions where conventional coils fail faster. Wherever they are installed – in roof installations, chillers or precision climate control systems – these first-class devices guarantee reliable and long-lasting operation with minimal maintenance requirements.

For business leaders and engineers who are looking for proven, highly efficient solutions specifically designed for environmentally friendly air conditioning systems, follow the link https://www.kaltra.com/microchannel-water-coils This provides direct access to technical information about the product and detailed technical specifications. Here, industry professionals will be able to learn how microchannel technology can be easily integrated into environmentally friendly temperature control methods in a wide variety of commercial and industrial premises.

This contributes to the transition to more environmentally friendly building systems.

As building regulations and energy efficiency standards become stricter, the use of complex thermal devices such as microchannel heat exchangers will increase. Their ability to provide high thermal performance while reducing environmental stress is a natural solution for environmentally friendly HVAC systems that seek to minimize energy consumption, refrigerant emissions, and total carbon dioxide emissions.

In addition to ensuring regulatory compliance, microchannel heat exchangers help businesses achieve corporate sustainability goals by saving energy and extending equipment life. The introduction of microchannel technology in the construction of a new zero-noise building or the replacement of an installed air conditioner is a promising investment in smarter and more sustainable climate management.

Microchannel heat exchangers – from reducing dependence on refrigerant and energy consumption to increasing the service life of the system and obtaining certificates for environmental friendliness – represent a comprehensive path to more environmentally friendly operation. For a specialist who needs to balance HVAC infrastructure with changing environmental requirements, the integration of microchannel-based equipment is not so much a technical innovation as a strategic step towards creating a cleaner and more efficient environment.

Ultimately, eco-friendly air conditioning is a new approach to the main components of the system. Microchannel heat exchangers, due to their efficiency, durability and environmental friendliness, are becoming the cornerstone of the future of sustainable climate control.